1. General Instructions

|

|

2. Disinfection

A- Preparation

- Instruments should be disinfected and cleaned immediately after use.

- Corrosive caustic agents and medicines- used in operations and for medical treatment- (e.g. silver nitrate, iodine preparations, and albotyl and mercury components) substances have to be removed immediately.

- Instruments must not store in physiological saline solutions as prolonged contact, otherwise causes pitting and rust.

- Handle and deposit instruments carefully after use. Undue "dropping" can cause damage to the instrument, for example hard metal tips on scissors may be chipped or small, delicate clamps can be deformed.

- Hinged instruments (such as scissors, clamps, and gouge forceps) have to be opened.

- Instruments should never be left overnight before cleaning as the risk of causing permanent damage increases with the length of time between use and preparation.

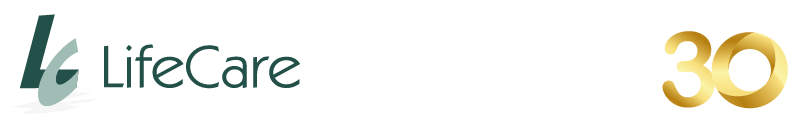

B- Manual disinfecting and cleaning

For manual preparations, instruments have to be immersed into a combined disinfecting and cleaning solution with proven disinfecting effect with the following precautions:

- The instructions of the manufacturer have to be strictly followed regarding concentration, temperature and induction time.

- Use fresh disinfecting and cleaning solutions every day. The following problems may occur due to using the same solutions for too long:

- Risk of corrosion due to soiling.

- Risk of corrosion due to increasing concentration caused by evaporation.

- Decrease if disinfecting effect due to excessive dirt concentration.

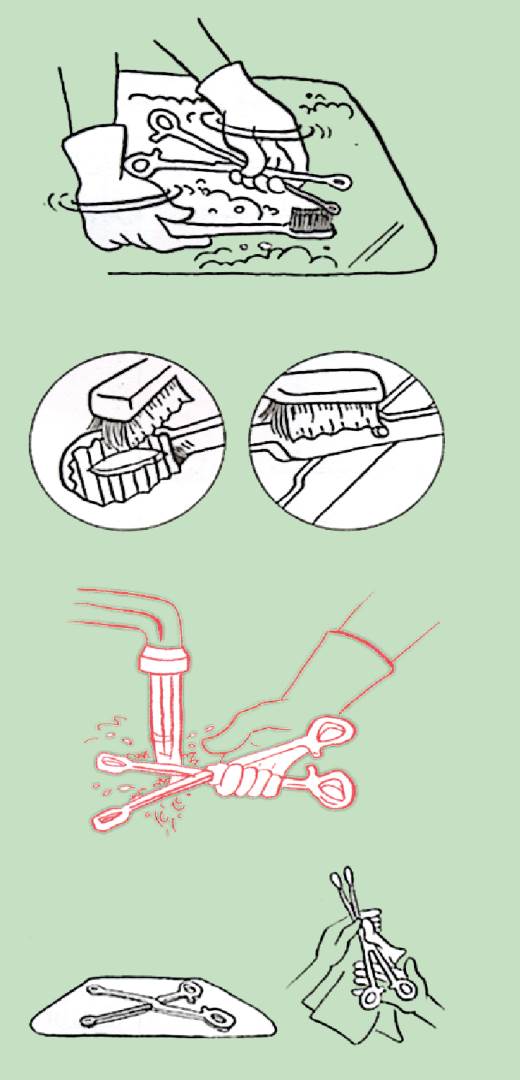

- After chemical disinfection and cleaning, the instruments must always be rinsed well under running water. Any residue has to be removed manually (no metal brushes, no scouring agents). In order to avoid water spots, a final rinsing with demineralized water is recommended. Finally, the instruments have to be dried immediately.

Drying with a pneumatic-air pistol is particularly safe and effective and should therefore be given preference over any other drying method. - For cleaning, it is recommended to use lint free soft cloths, plastic brushes or cleaning pistols.

C- Ultrasonic treatment

Ultrasonic treatment is particularly suitable for cleaning instruments of high-grade steel. Furthermore, ultrasonic treatment is a suitable method to effectively remove encrustations.

In order to achieve optimum efficiency of the ultrasonic treatment, please observe the following:

- Fill the bath to the markings.

- Add a suitable cleaning and/or disinfecting agent to the water

- Temperature above 40oC promotes degassing and cleaning.

|

|

- Large and bulky instruments such as lead hands or kidney trays must be placed in such a way that there are no wave shadows or inactive zones. Place such items either vertically or put them on top of the other instruments.

After ultrasonic treatment, the instruments have to be thoroughly rinsed either manually or by machine. Rinsing has to be performed with clear water of at least drinking quality or, better still, with demineralized water in order to avoid water spots.

The instruments should then be thoroughly dried.

3. Inspection

- After each cleaning, the instruments have to be macroscopically clean, i.e. free of visible protein remnants and other contamination.

|

|

- Ensure that the instruments function as they should or not. Fine and delicate instruments are inspected under the magnifying glass. *In order to avoid damage during transportation, place the instruments in specially designed racks or use special holding devices to prevent them from slipping.

- Faultless surgical instruments should not be packed together with instruments having damaged surfaces.

- Older instruments with chipped chromium and/or nickel coating may cause discoloration or corrosion on high-grade surgical instruments. It is, therefore, recommended to discard such instruments or pack them separately.